A method of thermosensitive, calcium and phosphorus based, chitosan gel production.

In vitro and in vivo cell cultures, arranged on biocompatible and biodegradable materials, are now used in osseous tissue regeneration processes.

A team from the Department of Environmental Engineering has designed and developed an innovative technology for chisotan gel production. The gel is formed at human body temperature and contains calcium and phosphorus in an atomic ratio, close to that in which these two elements occur in hydroxyapatite. It is intended for use as a as material for cell culture scaffolding structures.

This technology will be of interest to the medical industry.

Improvement of hydrophobic properties of ceramic bathroom tiles.

The hydrophobic character of ceramic tile surfaces improves their utility value and facilitates cleaning.

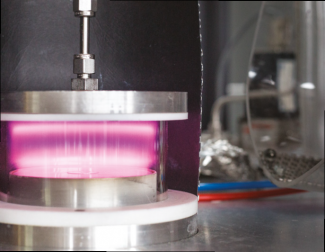

Research conducted by the Department of Molecular Engineering encompasses plasma modification of ceramic material surfaces by the deposition of a thin silicon-carbon layer on the ceramic surface. Plasma effects on the ceramic surface induce modification reactions, changing the properties and morphology of such surfaces. The application of this technology provides the surfaces of the ceramic products with highly hydrophobic surfaces.

This technology will be of interest to manufacturers of ceramic products.

A method of polymer pipe production – mainly for medical applications.

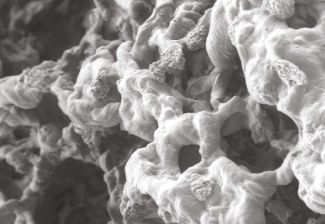

A team from the Department of Environmental Engineering has designed and developed an innovative technology for the production of polymer pipes from a homogenous chitosan solution in carboxylic acid water solution, containing dispersed hydroxyapatite.

Pipes produced as a result of this invention are varied in thickness depending on the duration of the electolysis process. They are biocompatible, bioactive and characterised by controllable and repeatable morphological and mechanical properties – perfect for use as scaffolding for nervous tissue reproduction.

This technology will be of interest to the medical branch.

Technology for reducing acid gas emissions from dry combustion processes.

Almost all combustion processes – fossil fuels, biomass or waste – produce acidic gaseous pollutants, which due to their properties pose a threat to the environment. Their emissions must be limited.

The use of dry technologies ensures effective acid gas removal and generates significantly lower costs. This technology allows for the verification of measurements, the development of technological concepts, the selection of equipment, the preparation of the installation design, technology implementation and optimization of the installation operation using calcium and sodium reagents. The experience of the Department of Environmental Engineering employees also allows for the design and commissioning of installations in heavy waste incineration plants.

This service will be of interest to companies from the heavy industry sector.

Package of tooling programmes ExAWZ.

Reducing the timeframe necessary for assessment of explosion risk may significantly increase safety levels.

A team from the Department of Safety Engineering has designed and developed the ExAWZ package, which is a tool to support semi-quantitative risk evaluations at work sites where explosive atmospheres may occur. The tool employs a modified method for the analysis of protective layers. This package is recommended for HSE teams, risk analysers, process engineers, designers, fire-fighting specialists, and for the authorities responsible for control and monitoring of labour conditions.

This technology is intended for industrial applications (fire-fighting and HSE departments).

Industrial safety.

Process safety management in industry.

This service includes the risk assessment of chemical installations, HAZOP, PHA and AWZ analysis, development of documents for Plants at Increased Risk and High Risk, modelling of cloud dispersion of toxic substances, fires, explosions and domino effects in chemical installations, substance thermal stability testing (APTAC, TSU, DSC) and development research in the field of photocatalytic hydrogen production or development research in removing exotoxins from wastewater.

We offer workshops in process safety management as a part of the service. Post-graduate studies in Industrial Process Safety have also been launched.

Measurements of rheological properties.

Knowledge of complex rheological properties and surface tension of liquids is necessary at the stage of designing and controlling technological processes as well as to determine the product quality in many industries.

This service offered by the Department of Chemical Engineering allows for a wide range of measurements of the reheological properties of liquid materials, including viscous and elastic properties, relaxation times, difference of normal stresses and thixotropic properties as well as determination of the change in hydrodynamic radius of colloid systems.

The offer will be of interest to the industrial sector.

Plasma techniques with product quality assessment.

Plasma modification of material surface properties (e.g. plastics and natural materials, fabrics, ceramics).

This service enables the use of atmospheric plasma in biodisciplines (e.g. medical biology, food technology), the deactivation of pathogenic microorganisms and the decontamination of food products.

We also offer analyses of molecular structure (XPS, FTIR, EDX) and surface morphology (SEM, AFM).

This service will be of interest to companies in the industrial sector.

Bioprocess services.

Ecological solutions for industry.

The services offered by the Department of Bioprocess Engineering allow for integrated biological and chemical treatment of industrial wastewater, pyrolysis and gasification of biomass, biodegradation of the organic fraction of solid waste and inertization of landfills, intensification of bioprocesses through integration of biosynthesis with separation and purification of bioproducts, removal of mercury from wastewater via biological methods and disintegration of organisms in bead mills.